Microplates

High-Throughput Screening product sector

For decades, Greiner Bio-One GmbH has been developing and producing plastic microplates that are used throughout the world in laboratories for diagnostics and research. Microplates for high-throughput screening (HTS) enable fast, automated analysis of a multitude of substances. This high level of efficiency ensures successful development of new drugs, for example.

With one of the world’s largest product ranges, Greiner Bio-One is a leading supplier of microplates. Besides microplates, used for drug screening, the company also offers special plates for immunology, protein crystallisation, DNA analysis and microsystem technology.

Greiner Bio-One is one of the innovation leaders in the sector. In a number of cases, new developments are carried out in close collaboration with customers such as Boehringer Ingelheim Pharma GmbH & Co. KG and Novartis AG, which benefit from the company’s decades of experience with various materials and surface modifications.

One of the latest developments in this product sector are non-binding microplates. By repelling protein, these surfaces optimise the biochemical screening for active substances, as the influence of the plate surface on the test result is reduced considerably.

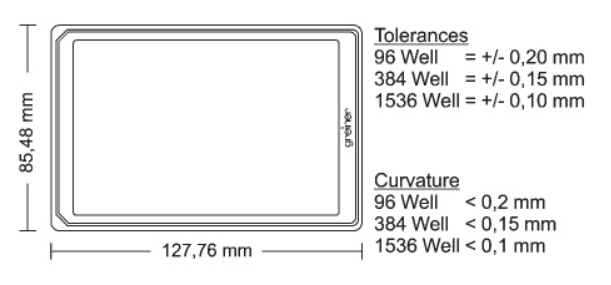

1. Standard Microplate Footprint

The manufacture of user-friendly products is one of our most important goals. All microplates manufactured by Greiner Bio-One have a uniform footprint (Fig. 1) which is conform to the recommendation of the American National Standards Institute (ANSI 1-2004). For detailed information about the external dimensions of our microplates and the conformity with ANSI standards, please ask for data sheets and customer drawings.

For further information about ANSI standards, please visit the society‘s website: www.slas.org.

Figure 1:

Footprint and tolerances of standard microplates

2. Material

Polypropylene (PP) and polystyrene (PS) are the standard materials used to manufacture the majority of microplates. Polystyrene is a highly clear polymer with excellent optical properties which makes it ideal for precise optical measurements. Polystyrene is also characterised by its ability to bind biomolecules, such as proteins, and it is therefore often used for manufacturing immunological products. Polystyrene is suitable for work with cell cultures.

Polypropylene is characterised by its excellent chemical and thermal stability. It is the ideal polymer for storage vessels or microplates. Polar molecules, such as proteins or DNA, are binding less to polypropylene than to polystyrene.

In addition to polystyrene and polypropylene microplates, Greiner Bio-One manufactures microplates with special requirement profiles, such as the UV-Star® microplates made from different polyolefins. These polyo lefins are characterised by their low level of autofluorescence, exceptionally high clarity, especially in the UV range, and greater chemical stability when compared with polystyrene.

A listing of chemical compatibilities of the main polymers used can be found in Greiner Bio-One forum No. 3

3. μClear® and UV-Star®

The move from isotopic to non-isotopic assays (fluorescence/ luminescence), and new applications in high-throughput and high-content screening increased the demand for clear bottom plates, microplates with pigmented walls and thin film bottoms.

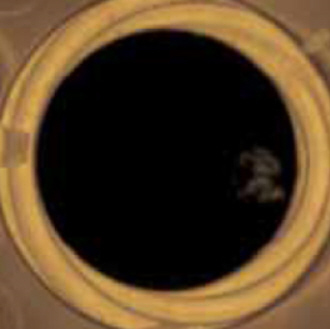

Up to now, clear bottom microplates have mostly been manufactured using a two-component injection moulding procedure by sticking or welding the components together. The development of a completely new and patented processing technique has made it possible for us to produce microplates with ultra-thin films, without the use of adhesives or solvents – the μClear® and UV-Star® products. This special method eradicates the risk of leaking wells (Fig. 2).

| a) | b) |

|

|

Figure 2:

Wells filled with methylene blue after threefold freezing and thawing:

a) single well of a Greiner Bio-One UV-Star® microplate

b) single well of a 96 well UV-transparent microplate of a competitor

The choice of suitable films is the decisive factor, and this will influence the quality of a clear bottom microplate. Strict controls before and during production guarantee a constant quality. Polarised light is either not depolarised (UV-Star®) or is only depolarised to a slight degree (μClear®) and the autofluorescence of the microplates is minimised.

The 96 well μClear® microplates and 384 well μClear® microplates have a film thickness of 190 μm +/- 20 μm. In the 1536 well microplates with a transparent bottom (μClear®) the film thickness is 75 μm +/- 10 μm.

UV-Star® microplates generally have a film thickness of 135 μm +/- 10 μm.

4. Black or White?

White microplates are usually used for luminescence measurements (e.g. Luciferase Reporter Assays) and black microplates for fluorescence measurements (e.g. Green Fluorescence Protein). The critical properties in these methods, such as background, autofluorescence or crosstalk are considerably improved by the use of black or white pigmented microplates. The optical and physical properties of the Greiner Bio-One microplates were investigated in our laboratory. Higher pigment concentrations produced a much lower autofluorescence of the microplates. At shorter wavelengths, this influence is more pronounced than at the normal fluorescein wavelength combination of 485/520 nm.

When comparing different white fractions, the same results were obtained for phosphorescence.

5. Non-binding Surfaces

Non-binding surfaces from Greiner Bio-One are characterised by their low binding capacity for biomolecules such as DNA, RNA, peptides and proteins. The repellent property of the non-binding surfaces for biomolecules can be advantageous in biochemical assays by increasing the sensitivity, reducing the background and improving the signal-to-noise ratio. Achieved through a chemical modification of the resin rather than a resin mixture with potential to leach, the non-binding surface from Greiner Bio-One is stable under common assay conditions and does not degrade during short-term storage.

6. Microplates for intelligent sample storage

The safe storage of samples and chemical substances is a fundamental part of Biology, medicine, and active ingredient research. Microplates are mainly used for storing samples, in addition to individual containers such as Cryo.s™, reaction vessels, and test tubes.

Tissue samples, chemical substances, proteins, nucleic acids (DNA and RNA), and other organisms (Nematodes, yeast, and bacteria) can be stored in microplates for long periods.

With their prearranged matrix, alphanumeric well coding, and, on request, bar coding, microplates facilitate optimum mapping and monitoring of samples, even for large libraries of substances.

Greiner Bio-One offers a large range of storage plates. Based on the field of application they are divided as follows:

• Classic: 96 well microplates made of polypropylene

The 96 well polypropylene microplates are perfect storage plates for active ingredients, biomolecules, and tissue samples.

• Screener: 384 well and 1536 well microplates made of polypropylene

Greiner Bio-One also provides various solutions for technically challenging, scientific questions requiring a parallel analysis of many samples. 384 well and 1536 well microplates are largely used in automated processes with high quality standards.

• High Performer: microplates made of cycloolefin for acoustic liquid handling

Acoustic liquid handling uses acoustic energy to transfer the smallest amounts of liquid from a storage plate into an assay plate. The benefit: the method is extremely precise and rapid; it reduces costs and prevents cross-contamination.

|

Greiner Bio-One microplates: • Are manufactured under DIN ISO 9001 guidelines • Can be traced all the way back to production through a defined LOT number system • Footprint compatible with automated systems • Are free of detectable endotoxins (0.03 EU/ml) and regularly tested using an FDA-approved kinetic turbidimetric LAL-test (Limulus Amoebocyte Assay) • Are analysed for detectable DNase, RNase and human DNA • Are manufactured without the use of siliconbased mould release • Are free of biozides and antistatics • Are manufactured out of raw materials tested for leachables • Barcode-labelling on request |